Power Generation Services

Minor Service

Perform generator and transfer switch checks. Frequency based on generator application.

Lube System

Gaskets/Seals

Oil Cooler

Oil Filter(s)

Oil Level

Sediment

Sending Units

Fuel System

Day Tank Operation**

Fuel Filter(s)**

Fuel Level

Fuel Lines

Fuel Pressure

Gaskets/Seals

Sending Units

Cooling System

Coolant Filter**

Coolant Level

Drive Belts

Fan Bearing

Freeze Point

Gaskets/Seals

Hoses

Jacket Water Heater

Conditioner/PH

Radiator Cap

Radiator Core/Tanks

Sending Units

Intake & Exhuast

Air Filter

Gaskets/Seals

Muffler & Flex

Turbo Charger

Rain Cup

Battery

Check specific gravity

Clean battery and terminals

Verify correct battery size

DC voltage

Load Test Voltage Drop

Load Test Amperage

Charger Output

Ignition System

(Spark ignited units only)

Spark Plugs

Ignition Wires

Distributor Cap

Rotor

Points & Condesnser

Ignition Module

Operational Tests

AC/DC Guages

Alarms & Shutdowns

Brushes & Slip Rings

Generator Bearing

Wiring Harnesses

Oil Pressure

Coolant Temp

Generator Outage Voltage

Frequency

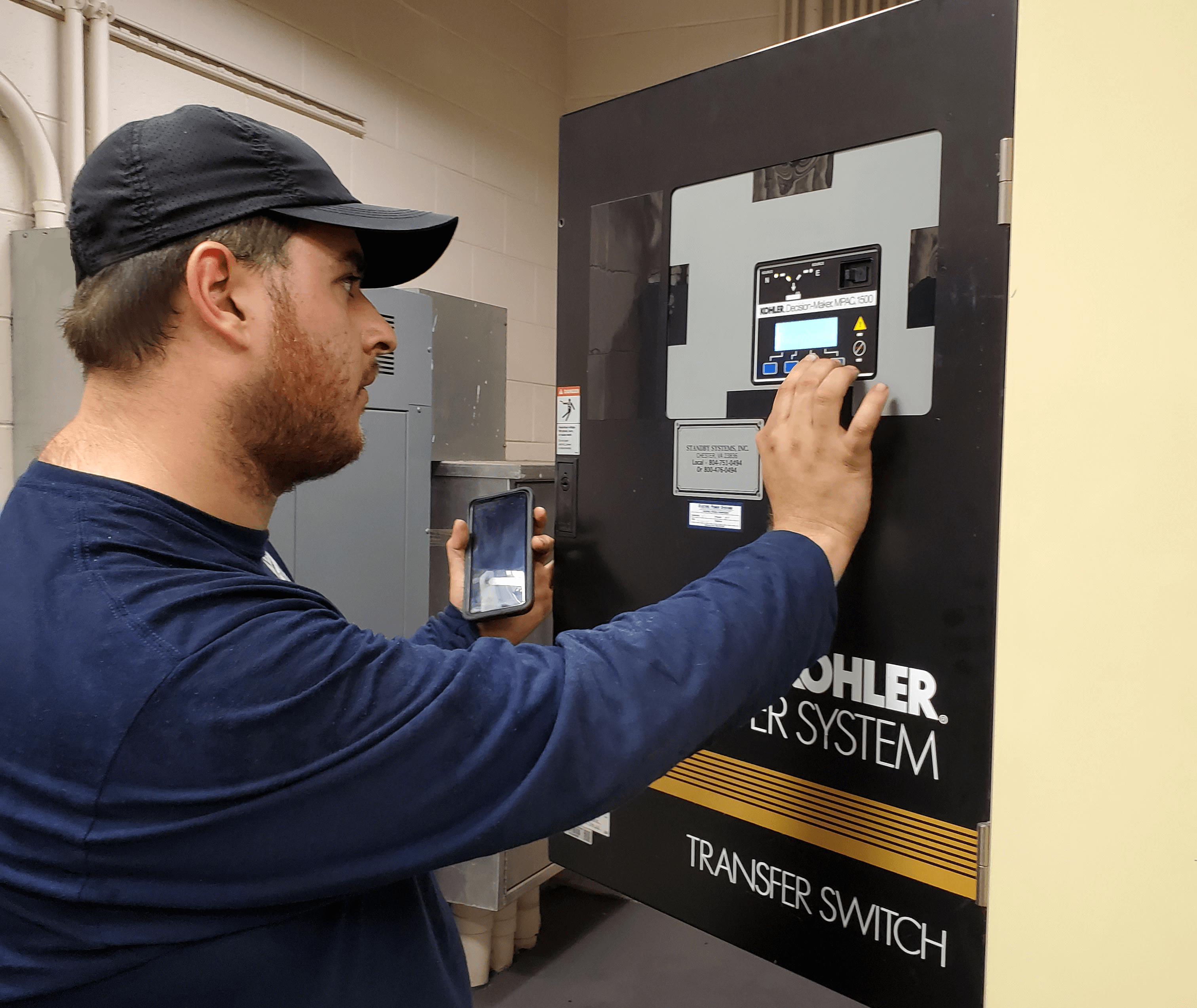

ATS Operation

Operational Integrity

Exercise Clock

MAJOR SERVICE

Change oil, oil filter(s) and fuel filter(s). Inspect coolant and air filter and replace as needed (filters sold at list price unless otherwise noted).

Included Parts

Oil

Oil Filter(s)

Fuel Filter(s), if any

Additional Charge

(only if required)

Air Filter

Coolant Filter

Coolant

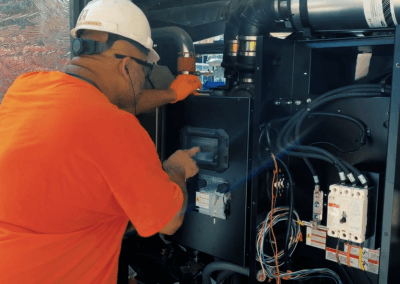

Resistive Load Bank Testing

Load test generator for 2 hours minimum with at least 30% of rated-nameplate capacity. It is recommended that load banks be performed annually. Load bank testing allows a generator set to be tested and the engine exercised under full load to verify its ability to perform in an emergency power situation, reduces risk of total loss of power at your facility, and prolongs the life of your power equipment. The test may also show problems that might not be readily apparent in a visual inspection. Load bank testing is even more important for diesel engines, as it cleans the carbon out of the injectors, the cylinders, the exhaust system, and prevents moisture build-up of internal parts. Additionally, load bank testing satisfies the requirements of NFPA 110, NFPA 99, NFPA 70, and JCAHO for load testing of stand-by Emergency Power systems.

Building Load Test

Transfers building load onto the generator to verify ATS switches from normal power to generator power as intended. Check system operation under building load to verify proper voltage, frequency, and generator operation. Inspect and test transfer switch and/or paralleling gear to determine automatic start and transfer of load. Check and verify proper operation of all time delays and transfers.

Coolant System Change

Drain and change coolant. The cost of the cooling system change also includes E.P.A. approved disposal of the waste material. It is recommended that the coolant is changed once every two years.

Replace Hoses & Belts

It is recommended that hoses and belts are replaced every four years.

Oil Analysis

The oil sampling and analysis program helps you monitor engine performance and identify potential problems before they cause serious damage to your engine.

Fuel Oil Analysis

Fuel that does not meet industry specifications or contains contaminants can dramatically decrease engine performance and fuel system life, cause premature filter plugging, and impact fuel economy. Regular testing of your fuel ensures that quality issues are detected early to avoid downtime. (Diesel fuels only.)

Coolant Analysis

The coolant sampling analysis programs help to monitor machine performance and identify potential problems before they case serious damage to the engine.